|

StrongArm is HySecurity’s multi-use, hydraulic barrier arm gate

operator. It is designed for ultimate performance, reliability,

durability, and low maintenance. This operator is best suited for

sites requiring long and heavy arms (up to 36 feet), high reliability,

synchronization with other HySecurity operators, spanning airport

runways, or controlling traffi c across wide openings. StrongArm is

often found on corporate campuses, Department of Transportation

applications, government facility parking lots, and multi-family

residences. StrongArm easily synchronizes with every HySecurity

operator for highly eff ective anti-tailgating measures.

Industrial Grade Components

StrongArm solves the problems common to most barrier arm operators: high maintenance gearboxes, sprockets,

springs, complex mechanical parts, and commercial grade or less components. All of HySecurity’s electronic controls

and mechanical/hydraulic components meet higher quality industrial standards. Electronics are protected by extremely

high surge-suppression (in case of lightning strike) and off er the ultimate in end-user-programmable functionality

with an ultra-low failure rate. With few moving parts, StrongArm is designed and engineered for the longest, low

maintenance, high performance lifetime.

Duty Cycle

StrongArm is certifi ed with a 1,000,000 cycle test and is specifi ed to run up to 2,000 cycles per day. StrongArms last

for generations and require very little maintenance.

Hydraulics and Chassis

StrongArm operates using an electric motor driving a hydraulic pump and cylinder. It has few moving parts. Most

parts are bathed in hydraulic fl uid and require no periodic lubrication.

StrongArm’s chassis is uni-body constructed with heavy-duty, 10 gauge welded steel that yields a very rigid, secure

housing, which is protected with catalyzed primer and polyurethane enamel paint for a resilient, attractive fi nish. The

galvanized sheet metal cover is secured by a keyed, T-lock for extra security and vandal resistance.

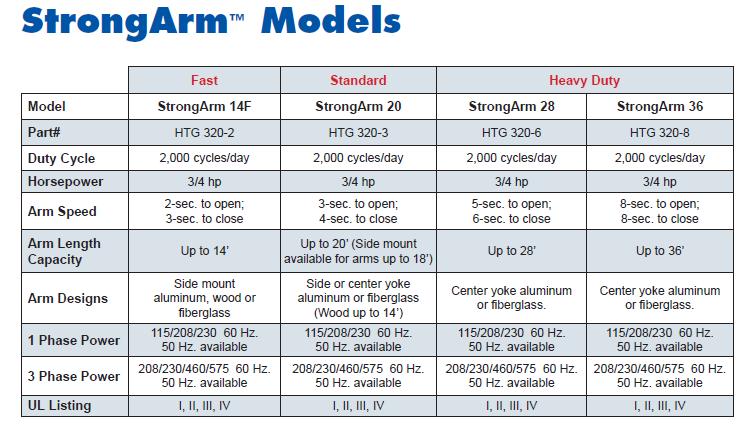

Models

StrongArms are available with a variety of barrier arm lengths, barrier arm types and cycle speeds. They can move up to 36 foot arms, come in side or yoke mounts, are manufactured with wood,

aluminum, fi berglass steel, or aluminum/fi berglass combinations. StrongArm cycle times range from 2

seconds to 8 seconds to open, depending on arm size.

Controls and Troubleshooting

StrongArm features the most advanced, fl exible and robust

controls in the industry. The Smart Touch Controller often

eliminates the high cost of add on, programmable logic controllers

(PLCs), providing on-board integration for even the most complex

perimeter security applications. Programmable options include

vehicle detector reverse or pause only, bi-directional traffic

(entrance and exit traffi c managed by one StrongArm), hold open

for two valid commands to open, master/slave, and timer-to-close.

Three user relays off er 26 programmable options, making it easy

to connect StrongArm to any external access control, obstruction

protection, or security device and create complex vehicle entry

validation, surveillance, and sequencing. Relays have normally-open

or normally-closed connections.

ADDITIONAL SPECIFICATIONS

• Various arm length combinations (10-feet to 36-feet)

open between 2 and 8 seconds. See model descriptions

for details.

• Available in two mounting styles depending on model:

side or center yoke; and fi ve arm options: wood,

aluminum, fi berglass, steel, or aluminum/fi berglass.

• Industrial grade mechanical and electronic

components, including high tensile steel, over-capacity

shafts and bearings, limit cams, and hydraulic cylinders.

• Rigid 10 gauge sheet metal chassis and 14 gauge

sheet metal cover is protected with a polyurethane

enamel fi nish over catalyzed epoxy primer yielding

an enduring, attractive appearance. Chassis tested to

withstand a 1,000-hour salt spray.

• Rated at 2,000 cycles/day

• Eff ortless integration with HySecurity SlideDriver and

SwingRiser for tough anti-tailgating operation.

|