Powermaster RJ Operator

|

Wiring Diagrams

|

|

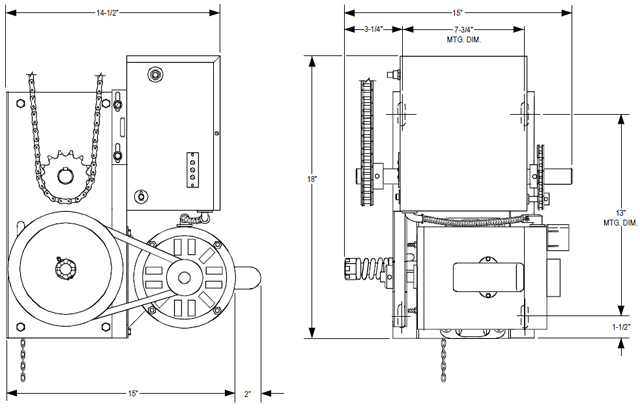

Model "RJ" V-Belt Jackshaft Release Operator

PowerMaster Model “RJ” operators are designed to allow emergency egress capability and lock bar sensing on Rolling Service Doors and Grilles.

Supply PowerMaster model "RJ" industrial duty jackshaft type operator to provide lock bar sensing and allow emergency egress on rolling service doors and grilles. Primary reduction shall be by heavy duty V-Belt Drive. Secondary reduction shall be a chain and sprocket arrangement. Reduction stages shall be arranged so that mechanism is self locking when torque is applied at output shaft. All reduction shafts shall be a minimum of 1" in diameter, supported by bronze oilite bearings. Operator shall provide an adjustable torque limiting clutch.

Motor shall be of the high starting torque, continuous duty industrial type, protected from overload by a current sensing or thermal type overload device. Motor controller shall be a heavy duty, full voltage, across the line, magnetic reversing contactor, that is mechanically and electrically interlocked. Electrical components shall be installed in a NEMA 1 enclosure integral to the operator. A transformer shall be provided to reduce control voltage to 24 VAC. Separate terminal strips shall be provided for connection of power supply line and all control devices. Operator shall be wired for an open/close/stop control station.

Installation Manual Installation Manual

Spec Sheet Spec Sheet

|

Control circuit shall provide instant reverse motor wiring on 1Ø operators. Positive chain driven, rotary type limit switches shall be provided to limit full open and close travel of door. Limit switch adjustment shall not be affected by removal of motor or by manual operation of door. A floor level manual disconnect chain shall be provided for emergency release and operation of door. An electrical interlock switch shall be provided to disable control circuit while emergency release chain is engaged. Final drive chain shall be a #50 or larger roller chain.

Electrical Specifications:

- High Starting Torque Motor with Full Overload Protection

- Solid State Circuitry with Power and Program Feedback LED’s

- On Board Open/Close/Stop buttons for service and adjustments

- Terminals labeled and grouped by function

- Auto-Detect monitored photo beam for simplified installation

- Selectable Operating modes B2, C2, D1, E2, T, TS

- Field adjustable built in functions including: timer to close, mid-stop, delay on reverse, lock bar sensing, maximum run time, etc.

Mechanical Specifications:

- For Use on Rolling Service Doors and Grilles to provide Emergency Egress

- Heavy Duty V-Belt and Chain Reduction, Mechanically Self Locking

- Heavy Duty #50 Roller Chain and driven sprocket Included

- Adjustable Torque Limiting Clutch

- Floor Level Disconnect & Electrical Interlock (For Manual Operation)

- Baked on Grey Powder Coat finish

|