Powermaster CT Operator

|

Wiring Diagrams

|

|

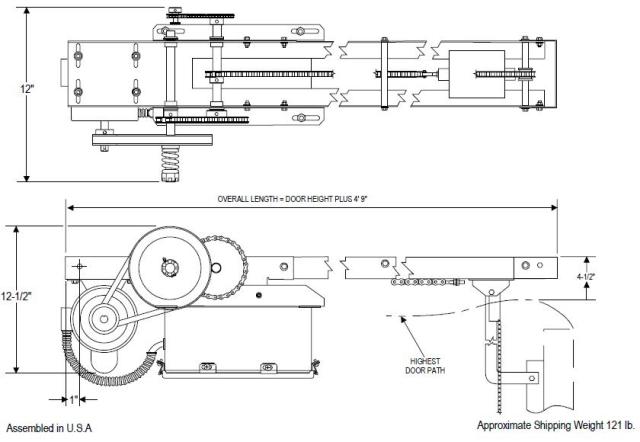

Model "CT” Carwash Drawbar Operator

Supply PowerMaster Model “CT” Drawbar Operator(s)

RATED ____ HP, ____ VOLTS, ____ PHASE, for

Carwash applications for use on Standard Lift Sectional Doors. Primary reduction shall be by heavy duty V-Belt

Drive. Secondary reduction shall be a chain and sprocket

arrangement. Motor shall be continuous duty industrial

type protected from overload by a current sensing or

thermal type overload device.

Motor shall be of the high starting torque, continuous duty

industrial type, protected from overload by a current

sensing or thermal type overload device. Motor controller shall be a heavy duty, full voltage, across the line,

magnetic reversing contactor, that is mechanically and

electrically interlocked

Installation Manual Installation Manual

Spec Sheet Spec Sheet

|

Electrical components shall be

installed in a NEMA 4 enclosure integral to the operator. A transformer shall be provided to reduce control voltage to

24 VAC. Separate terminal strips shall be provided for

connection of power supply line and all control devices.

Operator shall be wired for an open/close/stop control station. Control circuit shall provide instant reverse motor

wiring on 1Ø operators. Positive chain driven, rotary type limit switches shall be provided to limit full open and close

travel of door. Limit switch adjustment shall not be affected by removal of motor or by manual operation of

door.

An adjustable torque limiting clutch shall be provided to

prevent overloading of the operator. A spring set solenoid released brake, and a disconnect arm for manual

operation of the door shall be provided in case of power failure. The final reduction and drive shall be heavy duty

roller chain and sprockets. The drive shaft shall be supported by oilite bearings and be a minimum of ¾ In

diameter.

Electrical Specifications:

- High Starting Torque TEFC Motor with Full Overload Protection Removable without Affecting Limit Switch Setting

- Solid State Circuitry with Power and Program Feedback LED’s

- On Board Open/Close/Stop buttons for service and adjustments

- Terminals labeled and grouped by function

- Auto-Detect monitored photo beam for simplified installation

- Selectable Operating modes B2, C2, D1, E2, T, TS

- Field adjustable built in functions including: timer to close, mid-stop, delay on reverse, lock bar sensing, maximum run time, etc.

Mechanical Specifications:

- For Use in Carwash Applications on Standard Lift Sectional Doors, Rolling Service Doors & Grilles

- Heavy Duty V-Belt and Chain Reduction, Mechanically Self Locking

- Heavy Duty Corrosion Resistant Roller Chain Included

- Adjustable Torque Limiting Clutch

- Manual Disconnect Arm for Operation of the Door in case of power failure

- Operator Baked on Grey Powder Coat finish. Galvanized track.

|